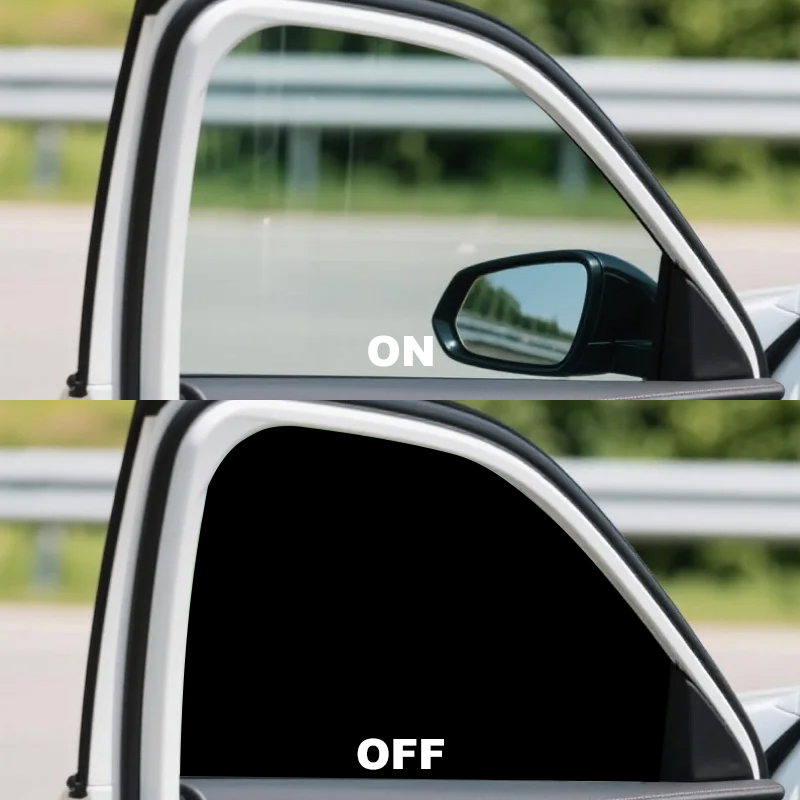

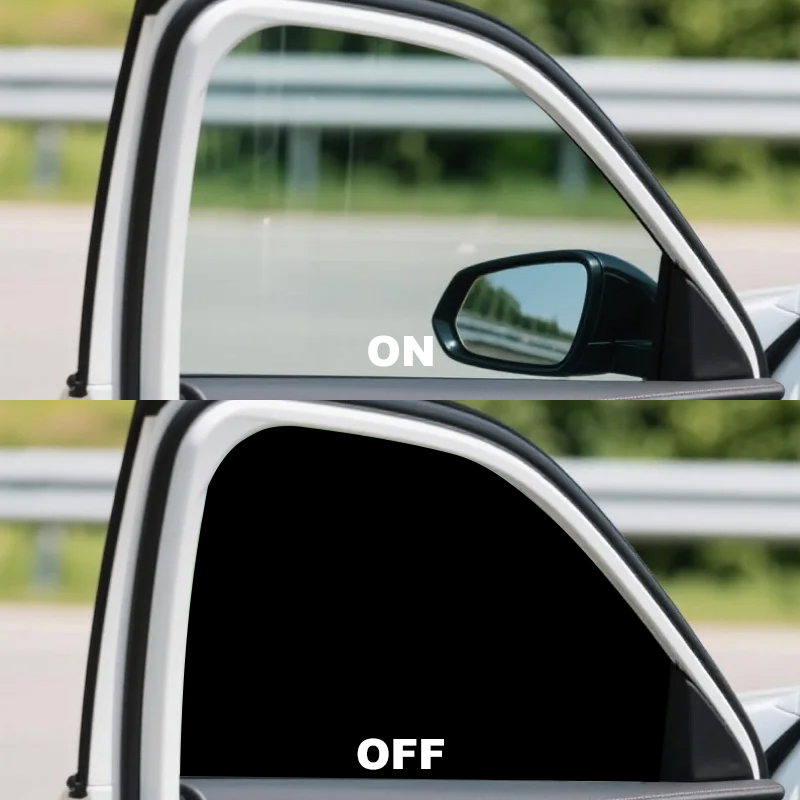

Glass, as a core component of modern architecture and vehicles, can achieve breakthrough performance enhancements through functional films. Automotive window films employ multi-layer material composite technology to impart comprehensive functions—such as heat insulation, anti-glare, privacy protection, and safety reinforcement—to ordinary glass. This article systematically details the industrial production process of such functional films, revealing the full-chain technical characteristics from raw material selection to finished product output.

1.Substrate Selection

Optical-grade polyester film (PET) serves as the primary substrate, meeting critical technical specifications:

Functional additives are compounded based on product positioning:

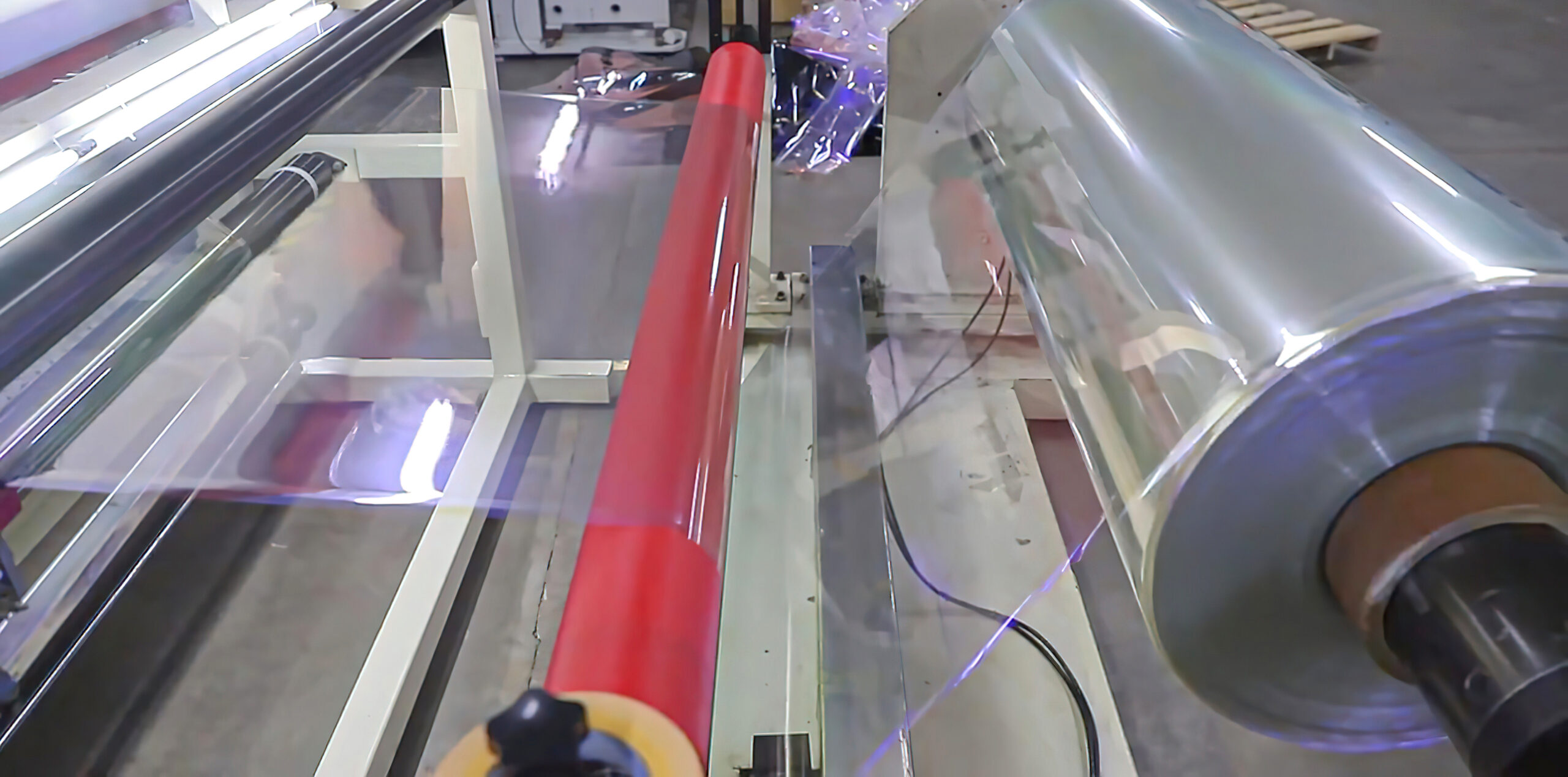

1.Melt Extrusion Film Formation

Twin-screw extruders execute melt casting processes under key parameters:

2.Surface Functionalization

Vacuum Deposition :

Wet Coating :

1.Adhesive System Design

Acrylic pressure-sensitive adhesive (PSA) formulations are optimized for:

2.Lamination Process Control

Thermal bonding equipment enables multilayer integration:

1.Nano-Ceramic Films

Plasma-enhanced chemical vapor deposition (PECVD) grows on PET surfaces:

2.Safety Anti-Explosion Films

Multilayer structure design :

1.Online Detection Systems

2.Reliability Validation

Compliance requirements :

Packaging : Vacuum aluminum foil bags with desiccants; transport at 25°C±5°C / RH 50%±5%.

Modern automotive window film manufacturing integrates materials science, surface engineering, and precision processing. Through molecular-level design, it achieves organic unification of light/heat management, energy conversion, and safety protection. KASHIBAGN Window Films advances technological innovation while maintaining cost efficiency, adhering to ISO 9001 quality management systems, and delivering solutions meeting the highest global standards.

No.6, Dongjiang Road, Eastward, Zhongtang Town, Dongguan, Guangdong

© Copyright 2022-KSB